Release Date:2023-03-31 10:29:55 Popularity:

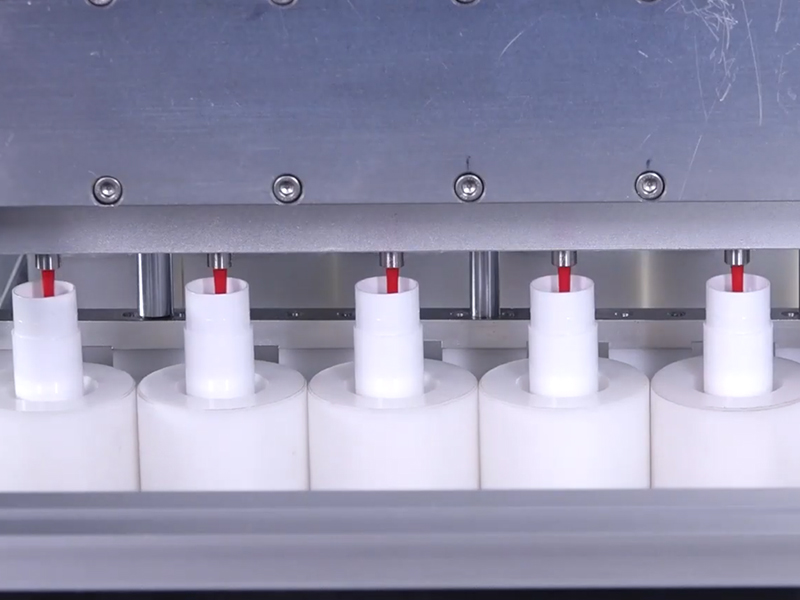

Multi-column back-seal granule automatic packaging machine is a high-performance, high-efficiency strip packaging machine. According to the requirements of packaging capacity and bag size, it can be made into 2-15 columns. Its biggest feature is that it can reduce packaging material consumption by 30% compared with multi-column four-side sealing packaging machines with the same packaging capacity. Sachets for powders, granules and liquids. It has the functions of automatic film feeding, metering, sealing, cursor tracking and positioning, counting, single bag or group bag cutting, packaging material deviation correction, batch number printing, finished product output and other functions.

Applicable products for automatic granule packaging machine:

1. Packaging of dripping pills and granules in the pharmaceutical industry.

2. Packaging of sugar, sweet seasoning, instant coffee and milk tea in the food industry.

3. The packaging of liquid beverages and jelly bars in the beverage industry.

4. Packing of oxygen scavenger, desiccant and Kanli sand in the chemical industry.

The characteristics of automatic granule packaging machine:

1. The control system adopts PLC program control, touch-type Chinese man-machine interface, two sets of servo system drive, bag-making length, packaging speed, counting, and instant notification of machine failure interface.

2. The up and down reciprocating movement of the horizontal sealing system is powered by a servo motor to complete the traction of the packaging film. The packaging material has no stretching deformation during the traction process, the photoelectric tracking is reliable, the length of the bag is accurate, and the horizontal and vertical seals of the packaging bag are smooth and beautiful.

3. Horizontal sealing is powered by a servo motor for closing and disengaging, and the movement track is controlled by a program during high-speed movement. There is no noise, the horizontal sealing strength is high, the packaging is more flat and beautiful, and the phenomenon of moisture absorption of packaging materials is avoided.

4. The frame film adopts the air-expanding shaft locking form, which is convenient, fast and reliable for film replacement and loading and unloading.

5. The full-page film is cut by rolling shears according to the number of columns. Fast cutting, durable and not easy to wear and tear.

6. The volume-adjustable measuring hopper of the translational movement is easy to adjust, and there is no phenomenon of throwing and grinding materials, reducing the damage and waste of granular materials. Customers save about 2 kg of materials per shift on average.

7. The overall frame of the machine is made of stainless steel profiles and plates, the surface is finely processed, smooth, easy to clean and disinfect.

8. The main electrical components adopt internationally renowned brands to ensure the stability and reliability of the control system.

9. According to the requirements of measurement size and packaging bag size, 4-6 rows of small bags can be packaged in back seal strips. According to customer requirements, it can be cut into single bag, connected bag, dotted line connected bag.

10. The parts in contact with the material are made of high-quality stainless steel, which meets the requirements of GMP. Relevant parts are modularized, easy to disassemble and assemble, and have strong versatility.

11. There are two ways of cutting, horizontal sealing clamping knife and independent cutting knife, users can choose freely according to requirements. Serrated cutter for easy tearing.

12. Optional: thermal transfer printer or ribbon printer, vacuum feeder.