Release Date:2023-03-31 09:53:45 Popularity:

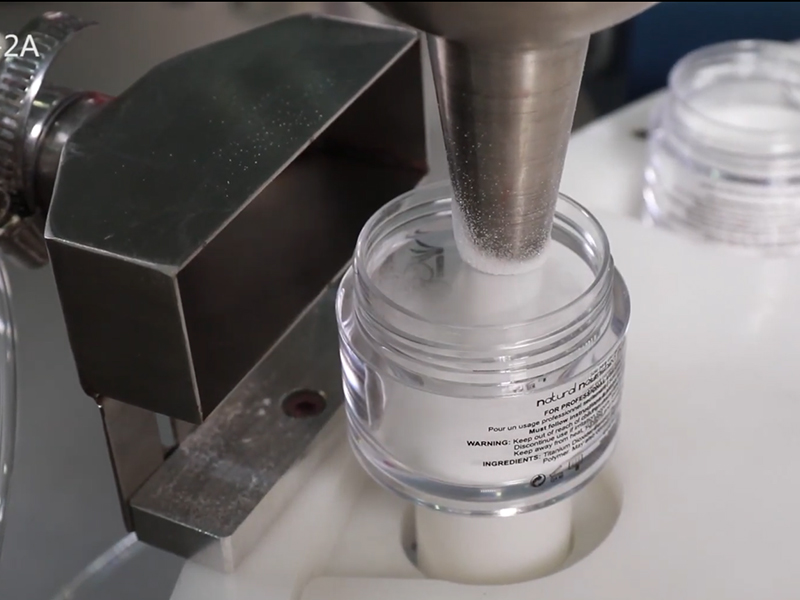

Granular packaging machine is a mechanized equipment for packaging granular products. When packaging products, packaging film is indispensable. The packaging film is made into packaging bags by bag making machine to hold materials, so as to carry out packaging , it can be said that the packaging film is a part of the core of the particle packaging machine.

Particle packing machine:

The packaging film is not unlimited. It may be gone after packing 5,000 bags, or it may be gone after packing 10,000 bags. It depends on the size of the packaging film. If the packaging film is gone, we need to replace it with a new one. After the packaging film is replaced, it cannot be used immediately. There are many matters that need our attention. Production and operation can only be performed after correct adjustments.

Matters needing attention after replacing the packaging film:

1. Pay attention to the stop position of the roller: after turning on the power switch, be sure to check the position of each roller of the packaging machine. The correct position is: the position when the granule packaging machine stops automatically, that is, the position of the sealing shaft (the middle shaft) The sealing side should be straight up. If not in this position, press scroll key to adjust. The purpose of this inspection is to prevent the sealing shaft from pressing against the film, causing the film to be scalded.

2. Temperature setting Pay attention to the lag of the actual temperature: the temperature set for normal use is 135 degrees, generally do not change it. If the sealing temperature is not suitable, you can also set the temperature, but it should be noted that the temperature of the sealing shaft will reach the set temperature after a delay of about 15 minutes. The range of changing the temperature setting value each time should not be too large. Generally, the variable should not exceed 5 degrees each time, so that the effect obtained will be better.

The above information is what we need to pay attention to after replacing the packaging film for the granule packaging machine equipment. Only when all aspects are adjusted can we start production and have a good packaging effect. If you want to know more about the granule packaging machine, you can contact GST Technology and ask your questions, and someone will answer them for you.