Release Date:2024-05-25 10:29:42 Popularity:

With the continuous progress of science and technology and the acceleration of industrialization, the packaging industry has ushered in an unprecedented innovation. Multifunctional automatic packaging machine as one of the core technologies of this change, is gradually replacing the traditional manual packaging methods, and has become an important and indispensable equipment on the modern production line. This article will discuss the characteristics and advantages of multi-functional automatic packaging machine and its application in various industries.

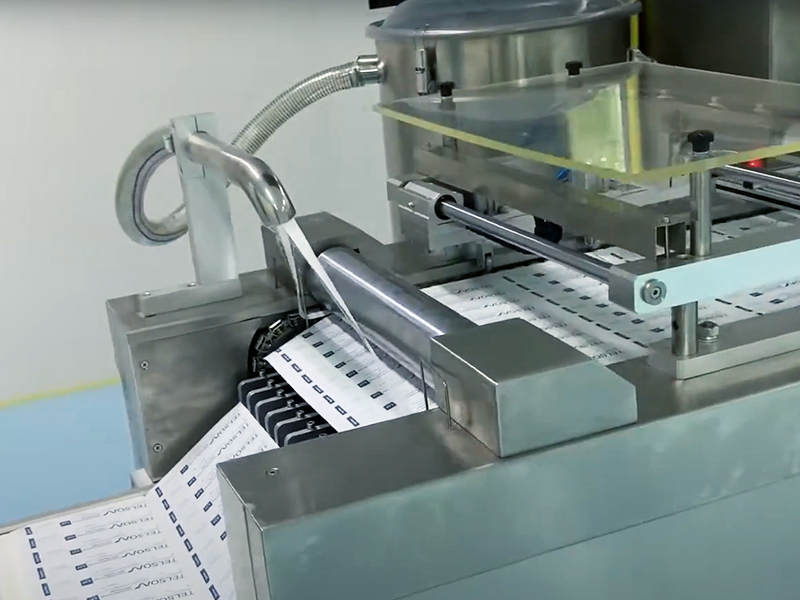

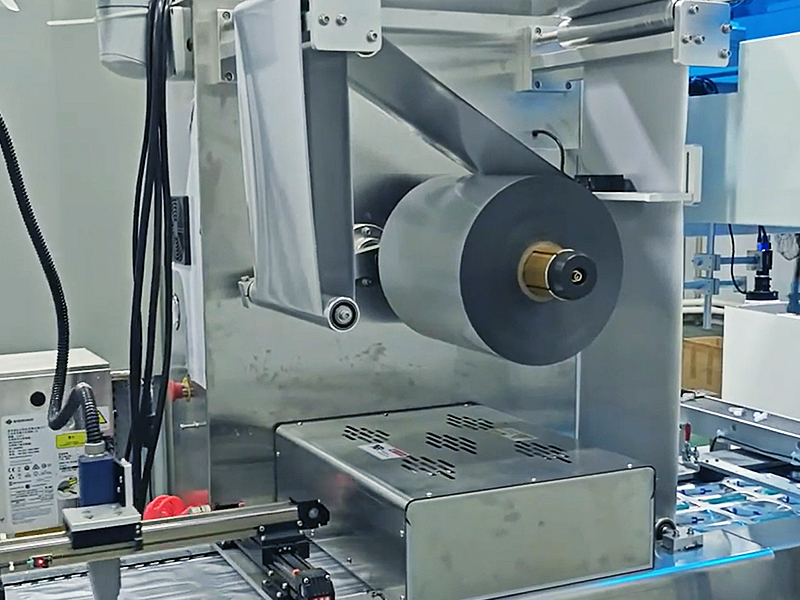

Multi-functional automatic packaging machine, as the name suggests, set a variety of packaging functions in one. These functions include, but are not limited to, automatic metering, filling, sealing, cutting, printing production date, labeling and so on. Its core feature lies in a high degree of automation and intelligence. Modern multi-functional automatic packaging machines are usually equipped with advanced PLC control systems, touch screen operation interfaces, and high-precision sensors and actuators, enabling precise control and efficient operation during the packaging process.

Another remarkable feature is its flexibility and expandability. The multi-functional automatic packaging machine can be adjusted and customized according to the needs of different products and packaging materials. For example, for materials in different forms such as liquid, powder, granules, etc., the packaging machine can be equipped with different types of filling equipment; for bags of different sizes and shapes, the machine can be adapted by replacing molds and adjusting parameters. This high degree of flexibility makes multi-function automatic packaging machine can be widely used in food, medicine, chemical, daily chemical and many other industries.

Advantages of multifunctional automatic packaging machine:

1. Improve production efficiency: multifunctional automatic packaging machine can significantly improve production efficiency. Compared with the traditional manual packaging, automated equipment can continuously carry out packaging operations, greatly reducing the time and error of manual operation. At the same time, a multi-functional automatic packaging machine can replace multiple single-function equipment, saving space and cost on the production line.

2. Reduce labor intensity: the use of automatic packaging machine can reduce the dependence on manpower and reduce labor intensity. Workers are only responsible for the operation and maintenance of the equipment, avoiding heavy physical labor and helping to improve the safety and comfort of the working environment.

3. Ensure the quality of packaging: Multi-functional automatic packaging machine can ensure the consistency of the quality of each package through the precise control system and high-precision actuators. Whether it is the filling volume, sealing strength or package appearance, it can reach a highly consistent standard to meet the consumer's demand for product quality.

4. Reduce waste and loss: automatic packaging machine has high precision in the measuring and sealing process, which can effectively reduce the waste of materials and loss of packaging materials. At the same time, automated production reduces the errors brought about by human operation, thus further reducing production costs.

Multifunctional automatic packaging machine in various industries:

1. Food industry: In the food industry, multi-functional automatic packaging machine is widely used in the packaging of various foods, such as puffed food, candy, cookies, instant noodles, spices and so on. Its high degree of automation can meet the hygiene standards and efficiency requirements of food packaging.

2. Pharmaceutical industry: the pharmaceutical industry is extremely strict packaging requirements, multi-functional automatic packaging machine can realize the accurate measurement of drugs and pollution-free packaging to ensure the safety and effectiveness of drugs. At the same time, the automation function of the equipment can meet the demand of mass production in the pharmaceutical industry.

3. Chemical industry: in the chemical industry, especially for some corrosive or dangerous chemical products, multi-functional automatic packaging machine can provide safe and reliable packaging solutions to ensure the safety of operators and product stability.

4. Daily chemical industry: Multifunctional automatic packaging machine is also widely used in daily chemical industry, such as detergent, cosmetics, skin care products and other packaging. Its flexible functions can adapt to a variety of different forms and specifications of product packaging needs.

In general, multi-function automatic packaging machine as a modern packaging industry, an important technological innovation, with its high degree of automation, flexibility and efficiency, greatly promote the production efficiency of various industries and product quality improvement. With the continuous progress of science and technology and the changing market demand, multi-functional automatic packaging machine will continue to play its important role and become an important direction for the future development of the packaging industry.