Release Date:2024-05-25 13:32:23 Popularity:

In the context of intelligent manufacturing and Industry 4.0, fully automated packaging machines, as efficient, accurate, and flexible modern equipment, are playing an increasingly important role in all walks of life. Fully automated packaging machines not only significantly improve production efficiency, but also show great potential in saving costs, improving product quality, and enhancing market competitiveness. This article will explore the main features, advantages and wide range of applications of fully automated packaging machines.

Characteristics of fully automated packaging machines

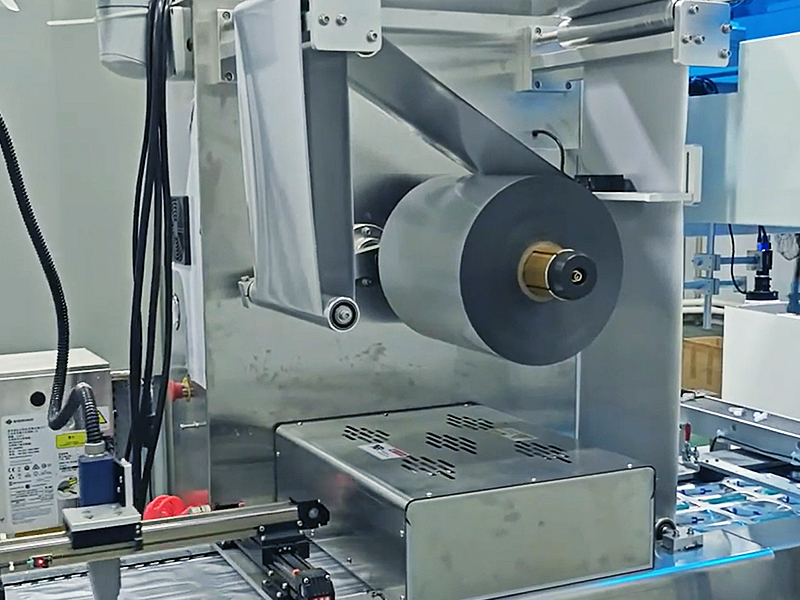

Fully automated packaging machines are known for their high degree of automation and intelligence. These machines are usually equipped with advanced control systems such as PLC (Programmable Logic Controller) and HMI (Human Machine Interface) to achieve comprehensive monitoring and precise control of the packaging process. Key features include:

1. Automated operation: From the supply of raw materials, product measurement, packaging material packaging, to the output of finished products, fully automated packaging machines can realize automated operations throughout the entire process, greatly reducing manual intervention.

2. Intelligent control: By integrating advanced sensors and control systems, automatic packaging machines can monitor and adjust packaging parameters in real time to ensure the accuracy and consistency of each packaging process.

3. Modular design: Fully automated packaging machines usually adopt modular design and can be flexibly configured and upgraded according to different packaging needs. For example, different types of filling heads, sealing devices and label printing systems can be freely combined to meet the packaging requirements of different products.

4. Efficient energy utilization: Modern fully automated packaging machines focus on efficient energy utilization and environmental protection when designing. Many equipment adopt energy-saving technology to reduce energy consumption and environmental pollution.

Advantages of fully automated packaging machines

1. Improve production efficiency: Fully automated packaging machines can continuously and stably perform high-speed packaging operations, greatly improving the efficiency of the production line. Compared with traditional manual packaging and semi-automatic equipment, fully automated packaging machines can significantly shorten packaging time and meet the needs of mass production.

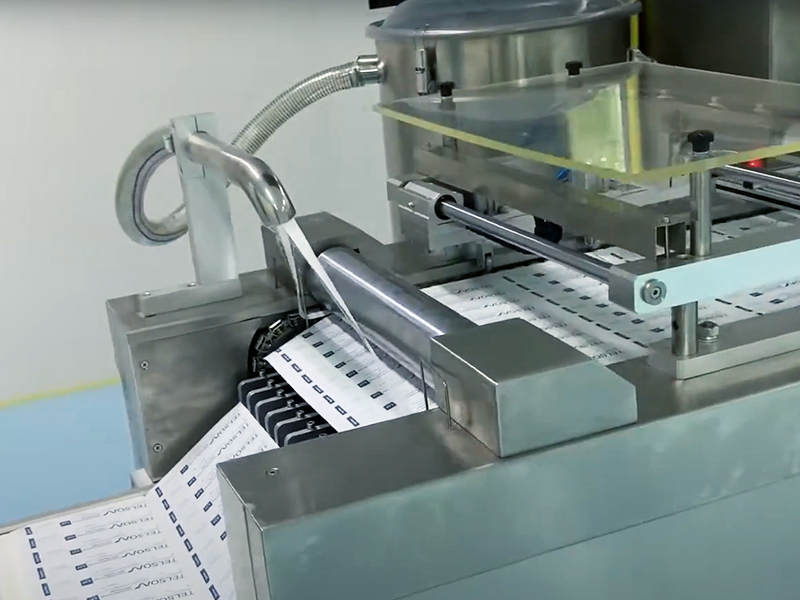

2. Ensure packaging quality: High-precision sensors and control systems ensure the precise operation of each packaging link, thereby ensuring the consistency and stability of packaging quality. This is critical to ensure product appearance, accurate metering and tight sealing.

3. Reduce labor costs: Fully automated packaging machines can replace a large number of manual operations, reducing the need for workers, thereby reducing labor costs. At the same time, the operation of automated equipment is relatively simple, requiring only a small number of personnel for monitoring and maintenance.

4. Enhance safety: The fully automated packaging machine is designed with operational safety in mind. Through multiple protection mechanisms and intelligent alarm systems, operational risks and equipment failures can be effectively prevented to ensure production safety.

5. Flexibility and customizability: Fully automated packaging machines can be flexibly adjusted according to the needs of different products and packaging forms, and are highly adaptable. For example, for products of different specifications, different types of packaging can be achieved by simply adjusting or replacing some modules.

Application areas of fully automated packaging machines

1. Food and beverage industry: Fully automated packaging machines are widely used in the food and beverage industry, such as beverage filling, food bagging, can packaging, etc. Efficient packaging capabilities and strict hygiene standards ensure food safety and shelf life.

2. Pharmaceutical industry: The pharmaceutical industry has extremely high requirements for packaging accuracy and sterility. Fully automated packaging machines meet the strict standards of pharmaceutical packaging and ensure pharmaceutical quality through aseptic filling, precise measurement and safe packaging.

3. Daily chemical industry: In the daily chemical industry, the packaging of detergents, cosmetics and other products requires efficient and flexible solutions. Fully automated packaging machines can quickly adapt to product packaging needs of different specifications and shapes, improving the flexibility and efficiency of the production line.

4. Chemical industry: The packaging of chemical products usually involves corrosive and dangerous substances. Fully automated packaging machines ensure the safety and reliability of the packaging process through special materials and designs, protecting operators and the environment.

5. Electronics and electrical appliances industry: In the electronics and electrical appliances industry, fully automated packaging machines are used for packaging various electronic components and finished products. They not only improve packaging efficiency, but also prevent static electricity and mechanical damage, ensuring the integrity of the products.

As an important equipment in the era of intelligent manufacturing, fully automated packaging machines are playing an irreplaceable role in various industries due to their high efficiency, accuracy and flexibility. By improving production efficiency, ensuring packaging quality, reducing costs and enhancing safety, fully automated packaging machines not only promote the modernization of industrial production, but also bring significant economic benefits and market competitiveness to enterprises. With the continuous advancement of technology and changes in market demand, fully automated packaging machines will continue to lead the development trend of the packaging industry and become an important pillar of future industrial production.