Release Date:2023-04-04 10:19:34 Popularity:

The use and operation of the granule packaging machine is a problem often encountered in the packaging industry at present. After all, it is now relying on mechanical equipment to work, and the use of manpower is gradually decreasing, so it is necessary to learn to better operate the granule packaging machine.

The main process and steps of operating the granule packaging machine:

1. Parts where it is best to refuel before starting the granule packaging machine, the sliding parts of the clutch and cutter clutch, the rotating parts of copper and copper alloys, and various parts with relative motion.

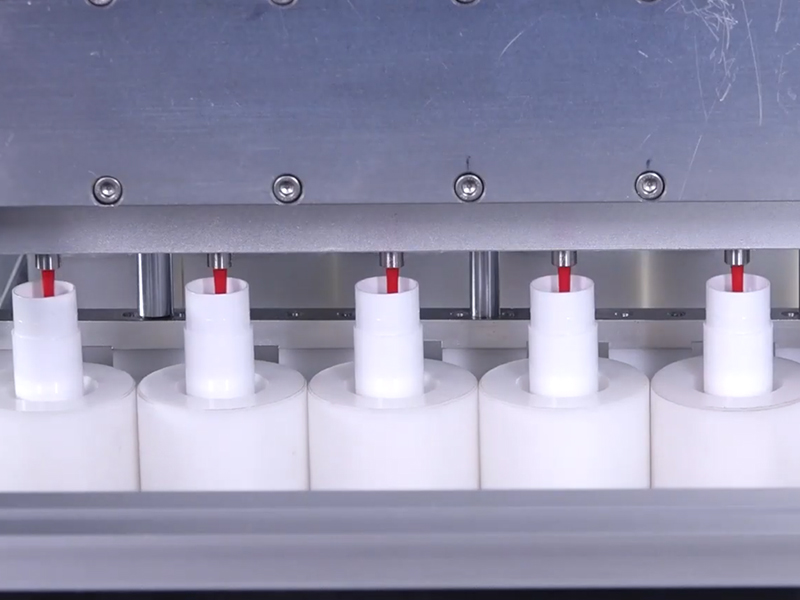

2. Turn on the power switch, the power indicator light is on, and after the power switch is turned on, the heaters of the horizontal and vertical sealing rollers can be energized and start to heat up.

3. Adjust the vertical and horizontal seal temperature controller to the required temperature. The temperature adjustment depends on the packaging material used. The temperature of vertical sealing and horizontal sealing is also different, and should be adjusted according to the sewing situation when using.

4. Place the packaging film, send the film to the vicinity of the vertical sealing roller along the guide groove, and align the two ends of the film. If the film is not aligned, it will curl during vertical sealing.

5. The computer sets the bag length to match the length indicated by the light point. First, measure the length indicated by the light point on the packaging material, which is set by the computer to set the bag length, that is, the actual length of the bag.

6. Run for a period of empty travel to see if it is well bonded. If the temperature is too low, the bag will be stretched and easily peeled off; if the temperature is too high, the heat-sealed surface will turn white, which is not beautiful. In addition, if the temperature is often too high, it will easily cause failure, causing the bag seal to melt or deform the bag seal.

7. Turn on the cutter clutch. When the cutting cannot be done at the specified position, cut off the power switch for adjustment.

8. The manual stepless variable speed pulley sends the film into the horizontal sealing roller, so that the light spot position of the film is just in the middle of the heat sealing of the horizontal sealing roller. Turn the left and right cams on the main shaft until the upper and lower micro switches are all open, so that the photoelectric head is just aligned with the light spot on the film.

9. Load the packaged materials into the hopper. Adjust the feeding time so that the packaged objects are filled into the bag when the horizontal sealing is completed. If it is not adjusted properly, it is easy to cause the packaged material to be caught in the heat-sealed part.